|

Xiamen Unipretec Advanced Materials Co.,Ltd

|

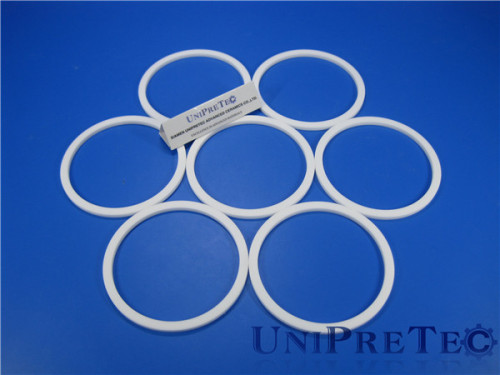

Technical Alumina Al2O3 Ceramic Wear Resistant Rings for Insulation Application

| Price: | 5.0~10.0 USD |

| Payment Terms: | T/T,WU;Paypal |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

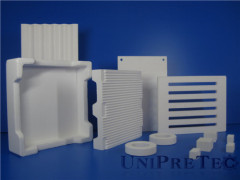

Unipretec can supply Alumina Ceramics / Zirconia Ceramics / Machinable Glass Ceramics / Boron Nitride / Silicon Nitride

Alumina ceramic seal rings are widely applied in mechanical and motional sealing for various types of household, agricultural and chemical pumps due to their outstanding mechanical strength,wear-resistance, chemical resistance and air tightness. Moreover, they are water-proof when the temperature changes sharply, they can meet the requirements on sliding and sealing properties in the actual use. They are widely used as mechanical sealing parts for metallurgy, machinery,chemicals, medicines, food, corrosion-resistant pumps, automobiles, pneumatic components etc.

The alumina ceramic seal rings which Unipretec produces can reach up to ±0.01mm in surface roughness and are suitable for mirror polishing.

Material Properties:

*Thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Electrical insulation (DC to GHz frequencies)

*Temperature resistance up to 1700°C

*Mechanical and electrical properties

*Resistance to all gases except wet fluorine

*Resistance to all common reagents except hydrofluoric acid and phosphoric acid

Alumina Ceramic Procucts Include:

1.Seal rings

2.Faucet valves

3.Tube and posts

4.Insulators

5.Nozzles for high pressure water machine

6.Sparkplugs

7.Eyelets

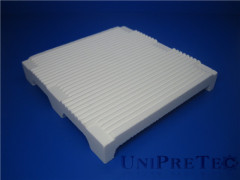

8.Plates for kiln

9.Valves

10.Spheres for milling

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.