|

Xiamen Unipretec Advanced Materials Co.,Ltd

|

Refractory Advanced Ceramic Components for High Temperature Application

| Price: | 5.0~10.0 USD |

| Payment Terms: | T/T,WU;Paypal |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Unipretec can supply Alumina Ceramics / Zirconia Ceramics / Machinable Glass Ceramics / Boron Nitride / Silicon Nitride

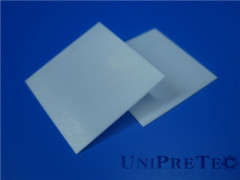

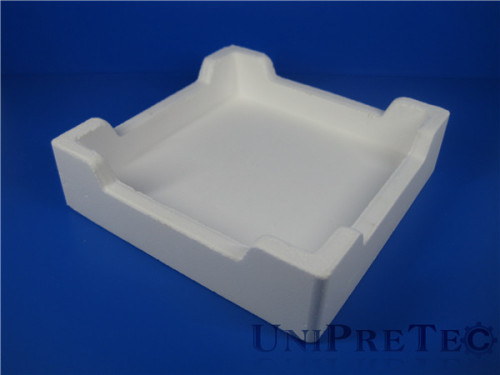

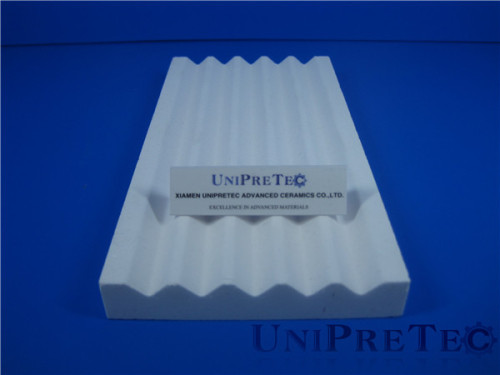

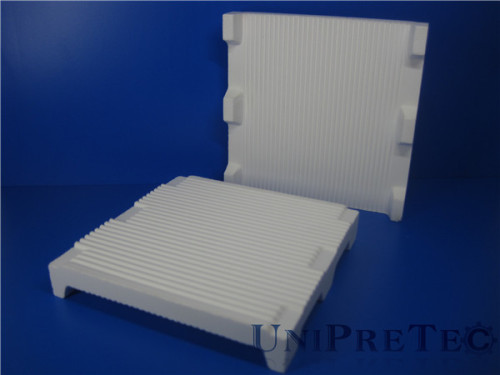

1.Material: Alumina Ceramic, Al2O3 Ceramic, Aluminum Oxide

2.Purity: 85%-99%

3.Color: Ivory, White

4.Product Feture:

*Good thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Temperature resistance up to 1700°C

Advanced ceramics is different from traditional ceramics.Traditional ceramics include clay products, silicate glass and cement,but advanced ceramics are ceramic products made from materials like aluminum oxide (Al2O3), zirconium oxide(ZrO2), silicon carbide(SiC), silicon nitride(Si3N4), boron carbide(B4C) etc. Based on the special property, advanced ceramics are usually used for high temperature application of Electronics Industry, Machinery Industry, Chemical Industry, Metallurgical Industry, Aerospace Industry etc.

Advantages of Advanced Ceramics

*High temperature resistance up to 1700℃

*Some kinds of advanced ceramics have high thermal shock resistance

*Corrosion resistance

*Good wear resistance

*Good dielectric properties

Various High Temperature Ceramic Products

1.Ceramic Thermocouple Tubes

2.Ceramic Setter Plates and Saggers

3.Ceramic Crucibles

4.Break Ring for Metal Casting

5.Components for vacuum furnace

6.Welding Nozzles

7.Ceramic Spark Plug Insulators

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.